The detention time challenge

One of the oldest principles of business is that it is better to act than to react. A proactive approach can reduce delays and costs associated with those delays.

In the trucking and logistics world, detention time is a significant challenge. Industry best practices call for 2 hours’ time from a truck’s arrival to getting loaded or unloaded, with all paperwork completed. Meanwhile surveys conducted by industry experts show drivers actually most often spend between 3 and 4 hours being loaded or unloaded.

When a driver is detained for any reason, the detention time leads to delays and costs. Drivers have, for decades, treated detention time as an unavoidable burden. In recent years, however, proactive efforts have been made to curb detention time.

Electronic logging devices offer a clear look at why loads are delayed. This insight can help carriers plan ahead to ensure detention time is reduced. Since ELDs provide real-time data, it is possible to immediately review why a driver gets held up.

Even better than that, however, is how well ELDs can identify patterns. If a particular shipper always seems to take extra hours to get a loaded truck out and on the road, for example, then a carrier can plan for that extra time instead of suffering a delay.

Some shippers are notorious for sloppy onsite logistics, ineffective loading practices or other causes of detention time. Anecdotal evidence from drivers is one thing. Data from ELDs can provide clear evidence that a shipper is causing problems, not a driver or carrier.

Feedback to a problematic shipper may help them to firm up their operations. In some cases, the insight may lead to carriers deciding to avoid a given shipper and work instead with more reliable links along the supply chain.

Geofencing as a detention time solution

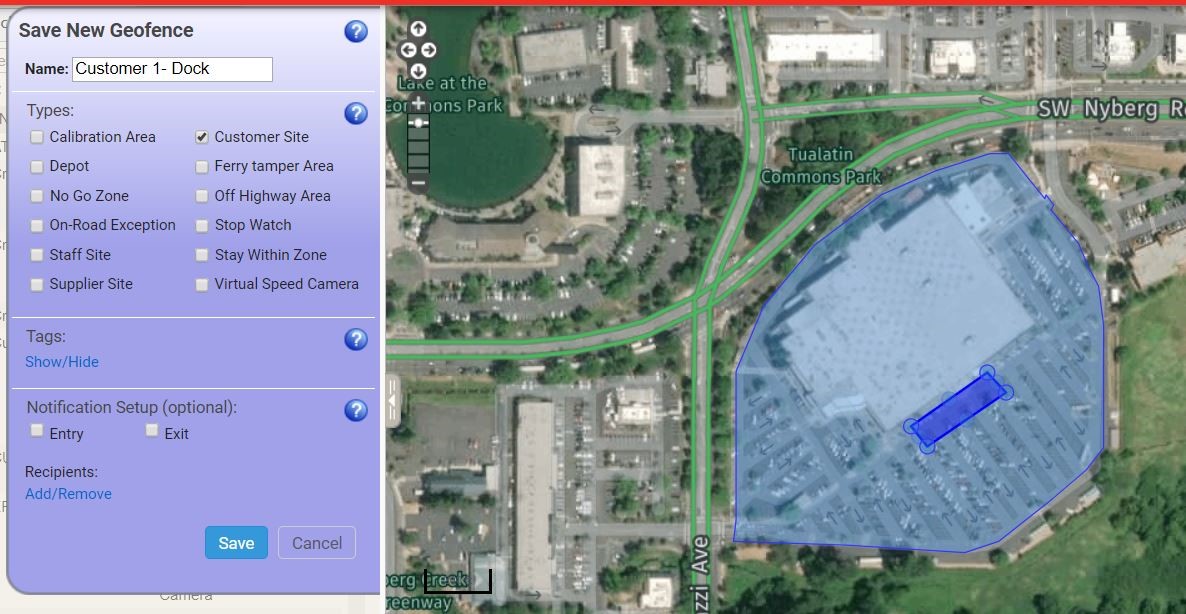

Geofencing, or creating digital “fences” that capture data for specified areas on a map, really help carriers drill down into detention time troubles. A fleet manager may create geofences to track visits to a defined area, including when a driver enters and exits the geofence, how many visits are made and total time spent there for a set time period (week, month, year, etc).

Industry-leading ELD software can even create a geofence within a geofence. Most geofences are created for a large area surrounding a customer, such as an entire port, industrial district or manufacturing/distribution center.

A smaller geofence within a geofence can be set up to capture data for a specific terminal, loading bay or other points of contact. By identifying the exact places where delays most often occur, you can plan ahead to avoid that area, or even bill for delays. Perhaps a specific time of day or day of the week is often when detention time occurs; ELD data sets make it easy to plan ahead and avoid these predictable delays.

EROAD’s geofence within a geofence tool

Costs of detention time

A 2018 report from the Department of Transportation shows more than $1 billion in lost pay due to detention. Meanwhile, only 3 percent of claims to shippers for detention pay are honored, ranging from $25 to $100 per hour.

Drivers in detention are less likely to make the next load on time. Customers rarely care if the shipper or carrier is responsible for delayed loads; they just want them to arrive on time. In a competitive market, carriers know that just one lost customer can seriously damage the bottom line.

This is why, once again, planning ahead is the best approach. With a system like EROAD’s you can use geofences to identify problem areas, improve relationships by communicating points of stress with shippers, and essentially boost productivity overall.

Future research and insight from ELDs will continue to solve the detention time problem. It will take time and effort, but detention is something the industry can address, rather than just plain accept.

Learn more about EROAD geofences and begin your journey towards a more efficient fleet.